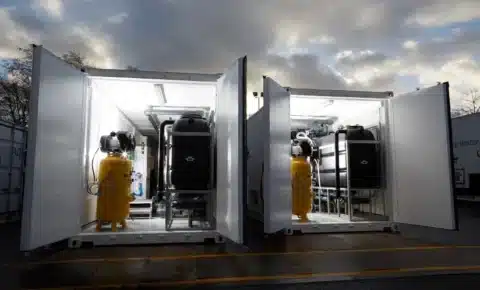

Bespoke Plant Rooms Tailored To Your Needs

With in-house conversion experts and a dedicated project management team, S Jones can provide your business with a highly secure, bespoke plant room which is tailored to your requirements.

With a range of standard sized products providing the basis for your plant room, you will benefit from a flexible and more cost-effective modular extension to your working environment, without extensive building work disruption or loss of on-site space.

Boasting decades of experience in project management and extensive equipment knowledge, we make installation and delivery of your plant enclosure to site as simple as possible.

Type Of Bespoke Conversions

See what our customers say about us!

Talk to our experts about your Plant Room and Enclosure needs

Contact Us

Why Choose S Jones?

Industry Experience

Distribution

Designers

Available

Certification

Choosing S Jones for your container solutions means selecting a partner renowned for exceptional customer service and unmatched speed of delivery. S Jones understands that efficiency and reliability are paramount. Our commitment to promptly meeting your needs without compromising on service quality sets us apart.

With a proven track record of delivering on our promises, we ensure that every interaction and transaction with us is smooth, quick, and entirely focused on fulfilling your specific requirements. Trust in S Jones to be the best option for seamless, speedy, and superior container services.